The job listing no longer exists.

Open Positions

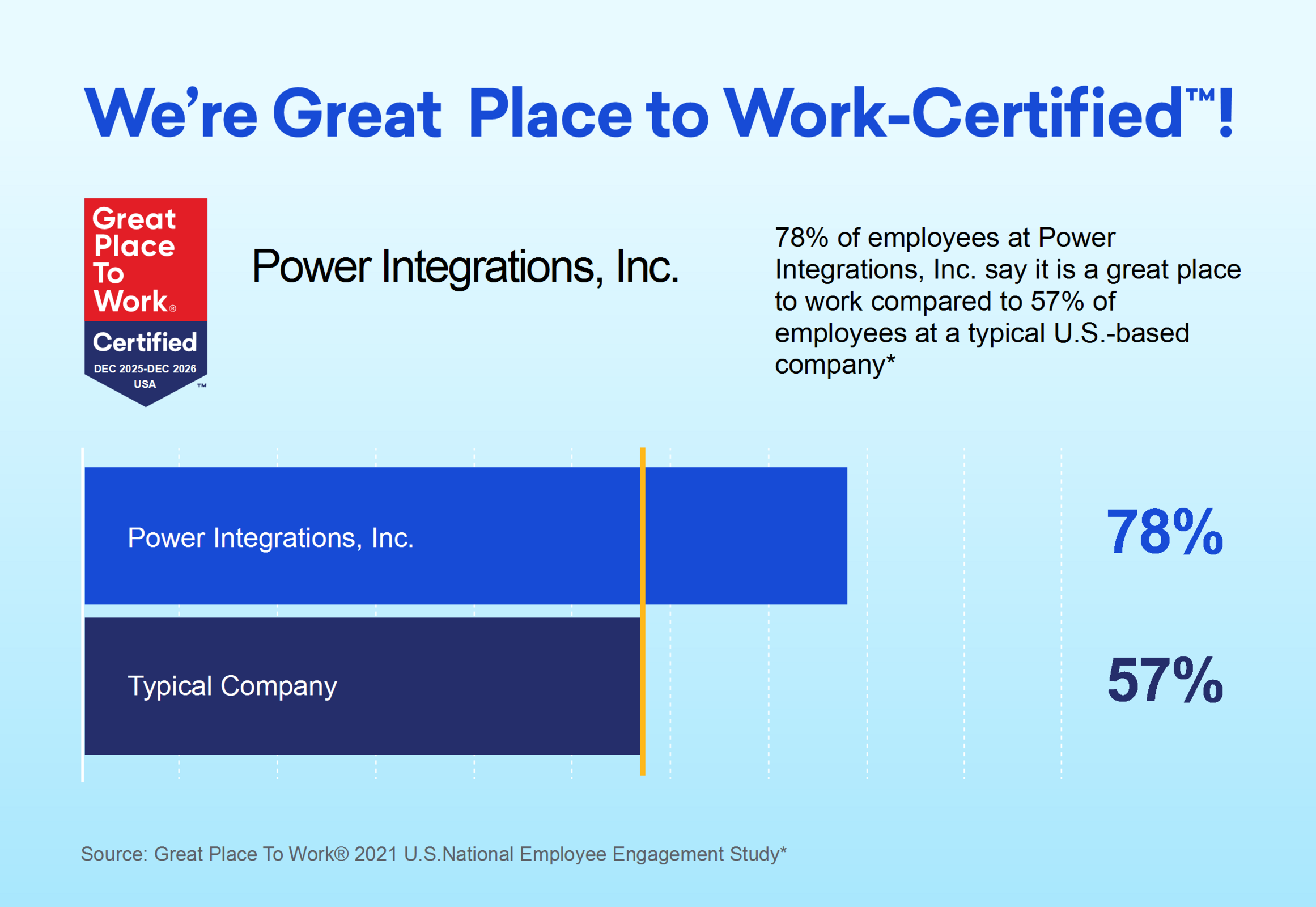

Power Integrations competes for the best talent. Our compensation packages consist of salary and equity, and they are commensurate with accomplishment. We offer a full suite of benefits.

It is the policy of Power Integrations to provide equal employment opportunity for all employment applicants and employees without regard to prohibited considerations of race, color, religion, gender, gender identity, gender expression, sexual orientation, age, physical disability, mental disability, marital status, or any other classification protected by applicable local, state or federal laws.

Engineering

| Job listing | Job location |

|---|---|

| Process Engineer | Branchburg, New Jersey |

| Staff Test Engineer - High Power | Penang, Malaysia |

Finance

| Job listing | Job location |

|---|---|

| Corporate Controller | San Jose, California |

| Senior Manager, Worldwide Revenue & Cost Management | San Jose, California |

| Senior Manager, Worldwide Revenue & Cost Management | Penang, Malaysia |

| Senior Manager, Worldwide Revenue & Cost Management | Singapore, Singapore |

| Senior Tax Analyst | San Jose, California |

General and Administration

| Job listing | Job location |

|---|---|

| Human Resources Manager | Penang, Malaysia |

IC Design Engineering

| Job listing | Job location |

|---|---|

| Digital Design Engineer | Pasig City, Philippines |

| Digital Design Engineer | Pasig City, Philippines |

| Digital Verification Engineer | Pasig City, Philippines |

| Senior Digital Verification Engineer | Pasig City, Philippines |

Marketing

| Job listing | Job location |

|---|---|

| Senior Product Marketing Manager | San Jose, California |

Operations

| Job listing | Job location |

|---|---|

| Director, Sourcing Management | Penang, Malaysia |

| Procurement Specialist | San Jose, California |

Product Development

| Job listing | Job location |

|---|---|

| Senior Product Development Engineer | Pasig City, Philippines |

Quality Assurance

| Job listing | Job location |

|---|---|

| Senior Failure Analysis Engineer (Automotive) | San Jose, California |

| Sr. Customer Quality Manager | San Jose, California |

Sales

| Job listing | Job location |

|---|---|

| Field Application Engineer | Vasanthanagar , Bangalore |

| Field Application Engineer | San Jose, California |

| Field Applications Engineer | Vasanthanagar , Bangalore |

| Field Applications Engineer | New Delhi, India |

| Field Sales Engineer | Mexico City, Mexico |

| Senior Field Application Engineer | San Jose, California |

| Senior Field Applications Engineer - India South | Vasanthanagar , Bangalore |

| Senior Field Sales Manager - India North | New Delhi, India |

Test Engineering

| Job listing | Job location |

|---|---|

| Engineering Intern | Penang, Malaysia |

| Test Engineer | Penang, Malaysia |

If you don't see a role that fits your profile, then apply with our General Application.

Check on an application you've submitted.

Sign up for Job Alerts.